Liberty Park Wastewater Treatment Plant

Enviro Services, LLC

Jefferson County, Alabama

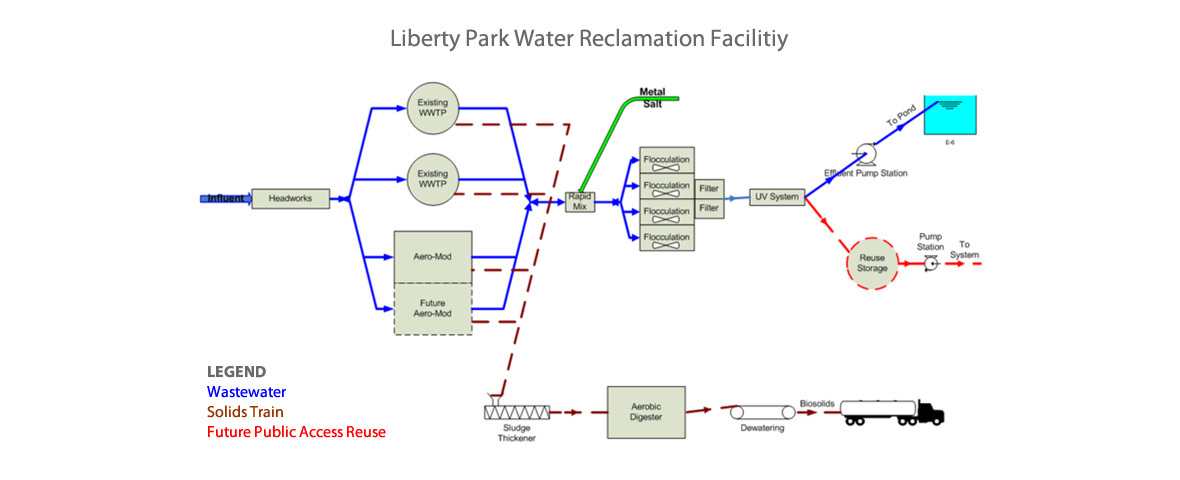

Engineers of the South lead the preliminary and design efforts for the Liberty Park WWTP Upgrades. The Scope of Work included the preliminary design of an advanced biological and physical/chemical treatment facility to comply with the anticipated new NPDES discharge permit which includes nutrient limits imposed as a result of the Total Maximum Daily Loads (TMDL’s) within the Cahaba River watershed. The treatment plant includes headworks, a biological treatment train with provisions for expansion, aerobic digestion, chemically enhanced primary treatment, tertiary filters, and ultraviolet disinfection.

The Liberty Park WWTP currently has two (2) circular field erected wastewater treatment plants with a combined design capacity of 700,000 gallons per day, followed by sand filtration, and ultraviolet disinfection. The treated effluent is pumped to a 30,000,000 gallon holding pond where the effluent can be distributed to the various outfalls. The current total phosphorus (TP) removal is accomplished by the removal of solids with some biological uptake of phosphorus and through chemical precipitation by the addition of ferric sulfate at the plant and in the system at some of the pumping stations. The chemical addition has been strictly for the purpose of odor control and has not been optimized for TP reduction.

Members of the EOS team did perform some pilot and full-scale studies at the Liberty Park WWTP that involved introduction of ferric sulfate at various dosing points and use of a WesTech ultrafiltration (UF) unit to demonstrate the high quality of effluent that can be achieved. The quality of effluent from the secondary clarifier during the several week demonstration test was relatively low in TSS that enabled direct feed to the UF unit with the result of TP less than 0.2 mg/l being achieved. The same controls on ferric feed for odor control were used in the study which were relatively crude but the results show a high quality reuse water are achievable. The impact of ferric injection on increase sludge production was not a part of this preliminary study but certainly observed.

The Liberty Park design team will be producing construction documents for WWTP improvements to meet the Phase I TP limits of 0.4 mg/l. The improvements will include a chemical feed system applying a metal salt, rapid mixer, flocculation basins, and new tertiary filters configured to optimize TP reduction. We have also provided a preliminary design of a solids handling flow train with aerobic digestion, and solids dewatering facilities to accommodate the resultant increase in solids produced.

The anticipated upgrades at the WWTP required to meet a TP limit of 0.2 mg/l would include a more sophisticated chemical feed system with provisions for polymer addition, pH control, an addition of tube settlers in the flocculation/clarification basin, and headworks. The timing of these upgrades would likely mean a capacity expansion which would include an additional activated sludge treatment plant utilizing a biological nutrient removal operational scheme.