Appeared in print as “Going the Distance” in Treatment Plant Operator Magazine in February, 2020

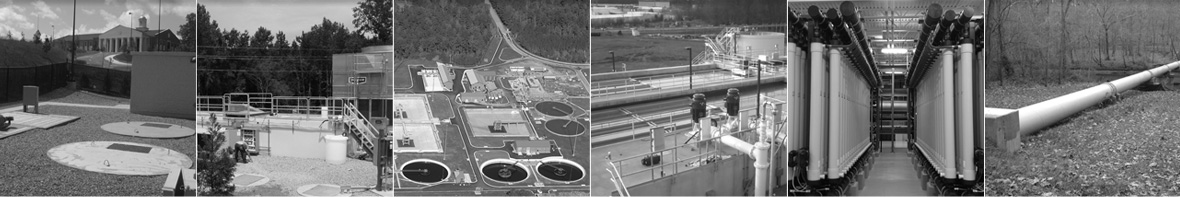

An Alabama team pulled out all the stops with a complete upgrade of a clean-water facility that includes a lime stabilization process yielding Class A biosolids.

When the City of Prattville, Alabama, decided to upgrade its Pine Creek Clean Water Facility, it spared no effort.

While the city had made incremental modifications in the past, the latest upgrade, completed in 2019, was designed to take the facility from simply adequate to boldly forward-thinking, fulfilling the city’s needs for at least the next quarter century.

A key to the new facility plan was a rethinking of solids handling, which had been basic and costly. Today, the Pine Creek facility uses a new approach to aeration, dewaters biosolids on a pair of screw presses and generates Class A biosolids for land application. The facility now accepts biosolids from the city’s other treatment facility for processing into Class A material.

Dealing with growth

Prattville, 10 minutes northwest of Montgomery, the capital of Alabama, is home to 34,000 residents and has seen impressive development. According to the Prattville Chamber of Commerce, more than 130 new businesses opened in the city and immediate surroundings between 2014 and 2018 — some $760 million in capital investment.

All that growth prompted city officials to look at existing infrastructure; it soon became clear that upgrades to the wastewater treatment systems were in order. “This was a wholesale overhaul of the entire treatment process to help deal with the growth in the area,” says Greg Thompson, project engineer with Engineers of the South, which had worked with the city for more than 15 years and helped design the upgrade.

“We were actively involved in the research and planning leading to the upgrade. The original facility, built in 1979 to comply with the Clean Water Act, had a 3 mgd design capacity. In addition to options for dealing with the increases in volume, we talked with city officials about rethinking the entire biosolids treatment and handling process.”

Thinking green

Though a facilitywide change was in the cards, the evaluation criteria for upgrades were highly ordered and specific. The desire to use state-of-the-art technology headed the list of desirables, according to Dale Gandy, director of Public Works.

“Obviously, we wanted to tap into the strengths of today’s newer technology,” Gandy says. “However, we also wanted to try to use green infrastructure within the plant. We had our sights set on looking into Class A biosolids. We wanted to create effluent cleaner than the environment into which it was headed. We wanted the whole effort to be energy efficient and needed the facility to have 25 to 30 years of viability.

“In addition, because we didn’t have unlimited funds to throw at the project, we had to be relatively cost-conscious. It was a long list to try to meet, but we set out confident that it could get done.” The facility envisioned by Thompson and his engineering team, working hand in hand with Gandy and the Prattville wastewater staff, would take the design flow from 3.0 to 5.7 mgd. That increase, they felt, would provide the needed life expectancy.

Making it modern

To get to that point, no area of the Pine Creek facility was left untouched. Designed as a conventional activated sludge facility, the facility headworks used a coarse screen in a deep sump ahead of the raw sewage pump station, followed by aerated grit removal.

“Aeration in the original design consisted of three parallel basins with two fixed-mounted, low-speed surface aerators per basin,” Thompson says. “Control of the aeration system consisted only of locally mounted low/high-speed selector switches.

“The process was energy inefficient, and the inability to aerate sufficiently or deal with varying flow rates and oxygen demands led to plant upsets and periodic effluent violations. The warm summer months, when effluent limits are lowest, made it particularly hard for operators to maintain compliance.”

At that time, liquid Class B biosolids were hauled to a farm field for land application. The facility averaged 10 to 15 6,800-gallon tanker loads per day. “But if it had rained and the field was wet, they couldn’t land-apply, so the plant had to be prepared to store material in the digesters,” Thompson says. “It’s not surprising they knew a change was needed.”

Finally, the previous clarifiers used a mix of organ-pipe and scraper-blade solids-removal systems. Disinfection, which originally used chlorine gas, was updated to UV in a 1999 facility modification.

In with the new

Thompson and his group worked hard to address all the issues with the existing facility and to ensure the new facility’s long-term viability. Influent passes through an all-new headworks with two fine screens (Duperon) and a grit removal system incorporating Eutek HeadCell technology (Hydro International) and WEMCO Pumps Hydrogritters.

In aeration, to deal with high ammonia levels caused by an inability to nitrify, the design team chose a VertiCel suspended growth activated sludge process (Evoqua Water Technologies). “VertiCel uses a combination of disc aeration followed by fine-bubble diffused air,” Thompson says. “In that way, we felt we could tap the efficiencies of both types of aeration to meet our need for an energy-efficient design and to get full biological nutrient removal. We always had issues getting enough oxygen transfer with the old system. The new combination powered by Howden positive displacement blowers is energy efficient and has great oxygen transfer.”

Road trip

To explore solids handling alternatives, city and engineering firm representatives visited several clean-water plants throughout the Southeast. One factor driving the city’s decision to create a Class A biosolids product was growth in the area.

“We were seeing new industries coming in regularly, and we knew we could soon run out of industrial fields like the one on which we’d been applying,” says Sam Russell, former Pine Creek plant manager who was brought on as a consultant during the upgrade. “So, we knew solids handling had to change and that dewatering would be a huge part of that discussion.”

Evaluation of dewatering options included visits to half a dozen facilities to view belt presses, screw presses and centrifuges and to converse with operators about their experiences with each. With the resulting information in hand, the group began seeing screw presses as the best fit for Prattville, and a visit to a plant in Immokalee, Florida, confirmed that impression.

“Immokalee was an eye-opener for us,” Thompson says. “That installation uses a Schwing Bioset screw press for dewatering and creates a Class A product using the Schwing Bioset solution. We saw so many similarities between what Immokalee had dealt with and our own situation at Prattville that we all felt we had found our answer.”

Pressing issues

Coming online in August 2019, the biosolids process at Pine Creek facility feeds mixed and aerated material from waste activated sludge storage basins to a pair of new Model FSP 1002 screw presses (Schwing Bioset). Each press is rated for 1,122 pounds of dry solids per hour, with a minimum 17% cake solids and a 95% minimum system solids capture.

While performance metrics were key to the screw presses’ selection, the Prattville team was also drawn by the self-cleaning function, where the units continue to dewater while cleaning cycles are performed. This ensures that no storage is necessary between dewatering and the Class A operations.

“We have each unit scheduled to clean itself every hour, but that function is flexible and easily changed,” says Napoleon Wilks, current Pine Creek plant manager. “We also like that these presses are almost self-operating. We have them programmed to run for only seven hours a day, five days a week, which allows us to keep staffing costs down.”

Achieving Class A

A key reason to develop a Class A product was that Russell and Gandy had backgrounds in farming and understood the benefits a soil amendment can bring and how it can be used.

“We like what can be done with a good Class A product, whether it’s for a resident’s flower beds, for grass in front of City Hall or for a farmer using it on crops,” Russell says. “We also felt there was a real upside in accountability to sourcing the dewatering and the Class A process from the same company.”

The Schwing Bioset process uses a screw conveyor to take dewatered biosolids to a twin-screw mixer where quicklime and sulfamic acid are added. From the mixer, a Schwing Bioset KSP-25VKL pump adds the material to a 22-foot-long reactor where chemical reactions raise the temperature and pH, stabilizing the mixture and creating a Class A product.

The material is maintained in the reactor at a minimum temperature of 131 degrees F for a retention time of 40 minutes, in accordance with U.S. EPA specifications for a process to further reduce pathogens. “The way we process our biosolids today, pushing a lower quantity through than our future design conditions, the material is actually in the reactor far longer than that,” Wilks says. “The result has been a consistently good Class A biosolids.”

The material is spread on a city-owned field and turned for a few days until it is dry enough to deliver to a farmer, who takes all the city can provide.

Reaping rewards

The city once hauled up to 81,000 gallons of Class B material per day to farms. Today, just two tri-axle trucks per week loaded three-fourths full can do the job.

“This is amazing to comprehend but, despite almost doubling the plant capacity, our energy consumption only increased by 8%,” Gandy says. “Thinking I must have missed something, I checked the data several times and even had a representative from Alabama Power verify it for me. There was no mistake — that’s how energy efficient this plant is.”

The biosolids process is working so well that the Pine Creek facility has begun processing material from the city’s 4 mgd Autauga Creek Clean Water Facility. That means hauling approximately 200,000 gallons of biosolids per month at 1.75% solids from the Autauga Creek facility to Pine Creek facility.

Gandy says, “We set out with a pretty challenging to-do list. But by tapping the innovative technology available to us, we feel we accomplished it all, and then some.”

Center of attention

Just outside the fence of the Pine Creek Clean Water Facility sits a structure built along with the recent facility expansion. Known as the City of Prattville (Alabama) Learning Center, the building signifies the city’s commitment to its clean-water process — today and in the future.

“In the long-term, this is something we felt could be as important as the upgrade itself,” says Dale Gandy, director of Public Works. “With so many wastewater professionals retiring and no one to replace them, there is a real shortage of the next generation of operators in the industry today. We hope to do our part to turn that around here.”

The city envisions the center becoming a site for continuing education for water and wastewater operators and a vehicle for promoting water treatment as a viable career.

“We will be bringing outside entities into the center to help train Prattville personnel in developing technologies, and we will invite other water and wastewater professionals in for training,” Gandy says. “We feel strongly about this industry and think this could be a real positive as we move forward.”